Emerson Climate Technologies Ltd.

The case study in pdf you can download here

APPLICATION:

The new layout design

BRANCH:

Heating technology

SECTOR:

Engineering

BENEFIT:

With the help of the simulation model in WITNESS there has been proposed a new layout of workplaces in the production hall which has been resulted by high time savings, space savings and thus costs savings too.

About the company

The company Emerson Climate Technologies Ltd. which is located in Mikulov in Moravia region is engaged in the production of heating, ventilation and ait conditioning, cooling and condesing technology. It is a part of the international company of the same name.

Project targets

The main target of this quite large project was to propose a new layout of one of the production lines, thus an optimal placement of individual production facilities in the current space with regard to respect of important material flows. The company was in these days planning a robotic workplace which should has be implemented to the new arranged production line. The next goal was to propose a hangling system for ensuring important material flows and deteminating a needed amount of handling facilities. The new layout of the production line needed a creation of a new work system and determination of workers´ number. A part of this project was the identification and elimination of processes which don´t add value to products and the other activities which are connected with the above-mentioned goals.

Solution

Through the analysis of data which have been provided by workers of the company Emerson Climate Technologies Ltd. there have beedn identificated main material flows, then according them the layout and placement of production facilities has been proposed in the current space. It have been proposed few variants of production facilities layout which three of them have been subjected to the further analysis. For this purpose it has been compiled the dynamic model in Witness. Againts of common process it has been created only one general model in this case which has been adapted to variants of production facilities layout.

Chosen characteristics (static utilization of workplaces, needed number of workers) have been counted at first by a simple statistic calculation (in Excel programme) and gained results have been used as input data for the dynamic model.

It have been tested three ways of workers´ assignment – the first was their free moving/walking according to whrere they were needed, the second way was according to their assignment on base of production tact (at grouping of production with regard to production tact) and the third way was to use of algorithm which grouped workplaces with regard to ensure production needed, minimalization its amount with a possibility to reduce crossing/walking of workers. The criterium for choosing an appropriate variant was using of workers and number of produced goods per week. From this comparison was the best way of algorithm of workers´ assignment. This algorithm was implemented to the dynamic model and used for the next deeper analysis. The result of this analysis was the determination of the best variant. For this variant was then made a more detailed solution.

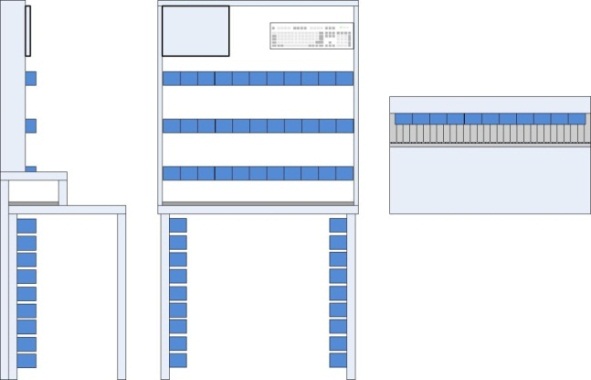

Pct. no. 1: The workplace layout design

Results

The result of this more detailed solution was the determination of workers´number for the particular produced amount, the detemination of buffer-stock amount and the optimal amount of pieces in a crate. It has been created to use a conveyor belt for handling with semi-finished products which would transport these semi-finished pieces among the individual workplaces. The size of the conveyor belt was determined according to these parametres.

For delivering of raw material it has been proposed a way of delivering the exact amount which is needed for the production of the finished products and at the same time in regular intervals. Then it has been counted the particular amount and the exact time intervals.

The one of the targets was to propose the workplace layout. This proposal is illustrated by Picture no. 1. The proposal of the final layout is on the Picture no. 2.

Pct. no. 2: The final layout design

The case study in pdf you can download here APPLICATION: The new layout design BRANCH: Heating technology SECTOR: Engineering BENEFIT: With the help of the simulation model in WITNESS there has been proposed a new layout of workplaces in the production hall which has been resulted by high time savings, space savings and thus costs […]