Grupo Antolin Turnov

The case study in pdf you can download here

APPLICATION:

The proposal of a new handling system in the dispatching warehouse

BRANCH:

Automotive industry

SECTOR:

Engineering

BENEFIT:

With the help of the simulation Witness model it have been verificated some of proposals of change of handling system and chosen an optimal variant for implemeting.

About the company

The company Grupo Antolin which is located in Turnov is a part of international group Grupo Antolin. The company is engaged in a production of plastic, rubber and upholstery products. It provides a research and developement and automotive industry.

Project targets

Currently, within the dispatching warehouse of the comany Grupo Antolin exists several routes for which operation are used some forklifts. From a data analysis it has been found out that up to 50 000 pallets were handled per month in the company. This quite significant number of transported units demands big amount of handling technology of which obtaining and operation are very financial demanding. Therefore the goal of this project was to count utilization of individual forklifts and propose the other handling system to decrease neccesary number of forklifts and number of operators.

Solution

It has been counted transported amount of the data form the client. These transfers have been separated to three categories according to a type of transported material (transports of raw material, semi-finished products and finished products). Individual types of transports have been separated according to projects in which the material belonged and on the basis of this separation have been assigned to particular loading and dispatching places at the layout. According to this separation there have been determinated transport routes for individual projects, points have been placed to the layout and transport distances have been counted.

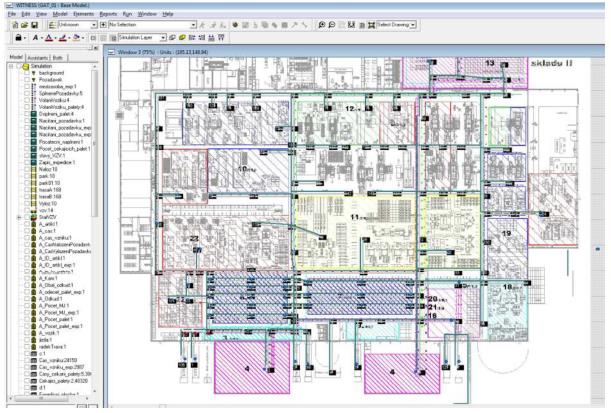

On the basis of an observation and gathered data it has been created dynamic simulation model in Witness (Lanner Group).

The demonstration of this model is on the picture no. 1:

After the creation of this simulation model there has been determinated dynamic workloading of all used forklifts. Then it have been verificated individual proposed change variants.

Verified variants were:

- partition of the hall to two parts with two or three handover places

- transport of raw material using a train, transport of finished products using a train – four pallets per train

- routes change of current forklifts handling

- pallet stockability with finished products – transporting pallets of two

Simulation results show that first three proposed solutions don´t bring sufficient improving of the state without an investment. Because one of client´s requirement was to propose a solution without a financial investment. A possibility of route changing of current forklift handling was refused too because the current layout was satisfactory. For another improving would be necessary to provide a change of this layout but it would be connected with an undesirable financial investment too. As the best appropriate solution it has been showed the transport of pallets in two pieces stacked on each other.

Results

From the dynamic model results it is obvious that pallets´transport with finished products is simplified too much that is possible to reduce forklifts by one and staff by three – so the savings are here:

- Year costs for a forklift – ca. 222 000 CZK => overall ca. 444 000 CZK.

- Year costs for a worker – ca. 250 000 CZK => overall ca. 750 000 CZK.

- The overall benefit of this project is ca. 1 194 000 CZK.

The case study in pdf you can download here APPLICATION: The proposal of a new handling system in the dispatching warehouse BRANCH: Automotive industry SECTOR: Engineering BENEFIT: With the help of the simulation Witness model it have been verificated some of proposals of change of handling system and chosen an optimal variant for implemeting. About […]