Optimization in heavy industry Vítkovice Inc., Kunčice Forge

![]()

The case study in pdf you can download here.

APPLICATION:

Management and optimization of job shop

BRANCH:

Heavy industry

BENEFIT:

The creation of a simulation model which is mapping the whole material flow. Reducing of time which product spent in furnaces at the press plant. The increase of dispatched pieces in furnaces. The optimization of production and the increase of presser utilization.

About the company

VÍTKOVICE MACHINERY GROUP is the most important engineering group with the strong position in chosen segments of the engineering production and at the area of big investment units. The group comprises about thirty companies. Vítkovice is nowadays the european leader in the production of steel bottles with the supermodern production line, it has almost the fifth rate on the world market of special cranked shafts for big marine ships. Vítkovice is one of companies which dynamically develop a project of car power from pressed natural gas. Vítkovice has certifications of many important reputable inspection companies.

The dynamic simulation

It is possible to successfully use the dynamic simulation also in heavy industry at job shop including the management and production optimization which is demonstrated by this project for Vítkovice Inc. – the creation of the simulation model of material flows in Kunčice forge, the presser utilization analysis, the bottlenecks finding, the determination of production line throughput with regard to a production portfolio and shifts.

The project proceeding passed off in these stages:

- The data analysis and the dynamic simulation passed off in a real production period from 1st January 2000 to 31st May 2000

- The simulation model building for the verification of contracted orders of a period from 1st January to 28 th February 2001

- The extension of dynamic model of Kunčice forge and finding of advantages of forge no. 1 provisioning

The simulation and the model

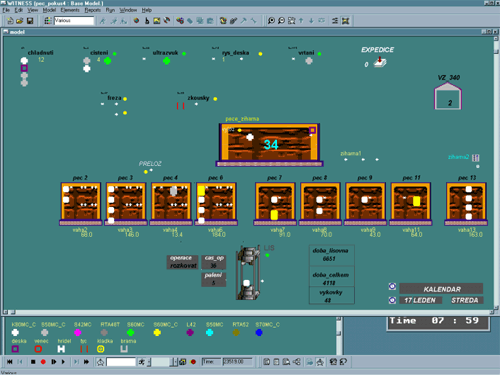

The model was created in cooperation with workers of the contracting authority, all changes and accessories were consulted to model corresponding with reality and it would be possible to use this model to manage and optimize the production. We have reached the authentic simulation model of the Kunčice forge, that means that the model involves the whole material flow map.

This model simulated the real production of the period from 1st January 2000 to 31st May 2000. The data came out from the production orders analysis for individual poducts and from furnace sheets. On the basis of these results the term of model building was prolongated because it was not possible to gain tha data in electronical form. The data were gathered from different sources:

- the production orders which affect only the press part (warms up, individual press operations,…)

- furnace sheets – from them was looked for the time of input warm up (or transport to other furnaces) and a course of heating porcessing at the annealing plant

The model is comprised of the press part where are displayed the individual furnaces (mobile and stationary) and the press. Then there is the annealing part where are not displayed individual furnaces but it is simulated as a complex and there are kept all the paramatres of heating processing. In the third model part are workplaces on which them take place the tests (here we use the average times which the products spend on them), the wokplace VŽ 340 where takes place burning, and dispatching to heavy mechanics.

The individual products move through the model exactly according their production method including all the stoppages and defects.

The simulation examples

The model demonstration

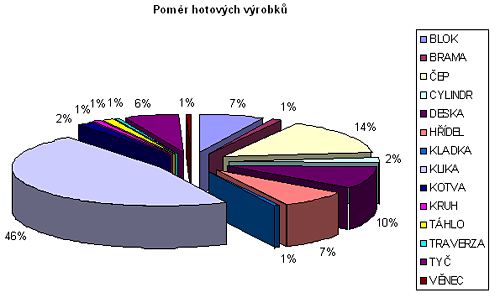

Percentage rates of product portfolios:

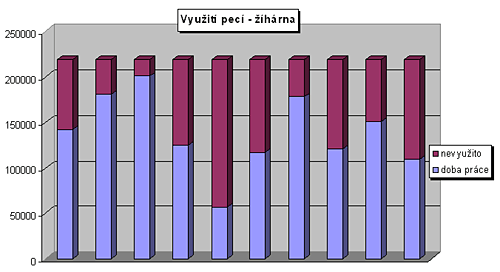

The graph of annealing furnaces utilization:

During the simulation was used the furnace no. 1, mainly for propeller shafts, after forging the ingot at octagonis the product placed to the furnace no.1 (instead of the annealing plant) and there past another operations (forging). After finishing these operations the forged product is moved to the annealing plant. It is faster production of forged products. With regard to a size of these products it is a big reduction of time and furnice capacity for the other products. One of the argumets for using the furnace no. 1 for propeller shafts is the quality of workmanship.

At the current production is uneven heating of the whole forged product (forged product must heat up to twice due to its size) and thus created a variety of material defects. All these factors were taken into account for the subsequent management and production optimization.

Notes.:

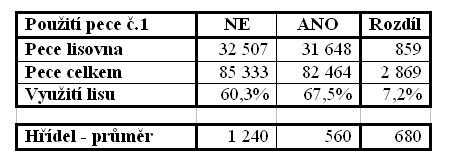

- all times at the tab are in hours

- pece lisovna (= furnaces press shop) … time which all products spent in furnaces in press shop

- pece celkem (= furnaces overall) … time which all products spent in furnaces in press shop and also in the annealing plant

The table shows that by using the furnace no. 1 results in a significant acceleration of the production of the propeller shafts while achieving a better quality parameters. Simultaneously using furnace no. 1 we will achieve shorter time to perform other products of reasons of freeing capacity furnace number 8 and 9, where it currently occurs warm up of the propeller shaft. Furthermore, there is a saving of time of the press work, since upon heating in a furnace no. 1 avoid operation flattening the middle, and to shorten the temperature profile T3.

No.1 furnace can be used for propeller shafts and as a collecting furnace. In this case, it is possible to use furnace No.13 as a helpful when congestion of the annealing plant for the cooling modes. When using the furnace No.1 also it showed that it is possible for one to two furnaces shut down, eventually. carried out on one or two furnaces periodic maintenance without interference to the production capacity.

The simulation was performed for three shifts and four-shift operation.

Results

The Analysis of the dynamic simulation results showed that four shifts during operation greatly accelerate the production and reduce the time which products spent in furnaces. This operation is very demanding for staffing all the shifts. Another problem is the repair shifts which are necessary for maintenance of machinery.

Therefore, there was recommended the three-shift operation where repair shifts can take place at weekends and four-shift operation can be introduced only for a short time if necessary.

For goog utilization of the furnace and press capacity is the most important factor the planning of the individual ingots coming to the press shop to cumulate the same operations (according to often press rebuilding) and to maximum full the mobile and stationary furnaces. For example to plan the coming of 12 ingots from which them are made middle pieces and pivots and ensure the same number of operations and don´t full the mobile furnaces and the stationary furnaces will be empty.

Due to our proposal it was ensured the uniform fulfillment of both types of furnaces (mobile and stationary) thereby the overall time of products in furnaces is decreased.

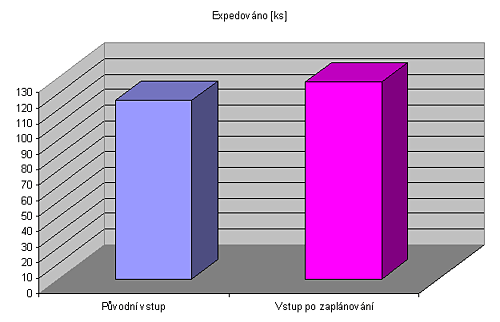

Dispatching (pc). Violet – former input, pink – input after the planning

For the same number of finished products (for January and February 2001) there was a significant reduction in the time spent by these products in furnaces press. Time spent in furnaces totally increased because of the increased number of shipped units.

It can be stated that the changes made in the planning of incoming ingots were able to improve the production, reduce the time that products are in furnaces for the annealing shop, and increased utilization of the press. These factors were then tested in a pilot project, management and optimization of production, during which the use of a simulation model to optimize the production plan.