Třinecké železárny Inc. – Moravia steel

The case study in pdf you can download here.

APPLICATION:

The material flow verification

BRANCH:

The production of rolled steel products

SECTOR:

The production and dispatching

BENEFIT:

Due to the analysis of the production current state and the simulation of the current and presumed state in 2015 there were proposed few measures which could increase the efficiency of the production.

About the company

Třinecké železárny Inc. produces long rolled steel products. The company was established in 1839. The company produces almost a half of steel in the Czech republic now. The majority owner is one of the biggest czech trade company – Moravia Steel.

Project targets

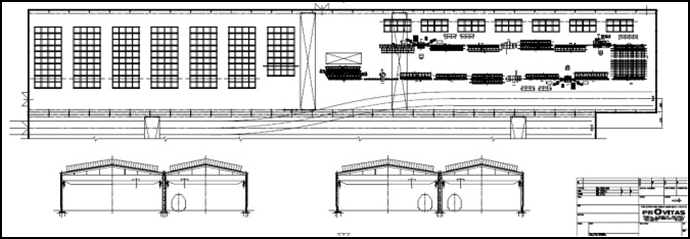

The project target was to verify the anticipated production volume at the annealing plant in the year 2015 using the dynamic simulation. The other target was to verificate the production and storage capacity and the amount of handling technology.

Solution

The analysis of the current state was an important part of this study and the verification of the gained information as first by the built simulation model of the current state and after the validation it was built the simulation model of the presumed state in 2015.

It was neccessary to become acquainted with the materiál flow in the production and with the related analysis of reported operations and it was neccessary to chart all the workplaces (machines, facilities) of the annealing plant, adjust the gathered data to the needed form and perform the analysis of the workload standard and reported operations.

For the vefification needs it was performed the cumulative counting of the performance on the all key workplaces. For the most accurate model creation was neccessary to perform the analysis of production downtimes. It was performed also the analysis of the annealing plant for the right dispatching implementation to its simulation model. The current state simulation model was built on the basis which were taken from the performed analysis of obtainable watched periods. The logic and concept used in the current state model was subsequently used for the creation of the presumed state model in 2015.

To the presumed state model were included new facilities in the annealing plant of stainless steel (and removing needless facilities), the planned production volume in 2015 – the order structure, materiál handling methods and the dispatching.

After incorporating all the assumptions could be performed the simulation experiment that pointed out how the equipment and handling technology would be utilized at the expected state in 2015. After the presumed state in 2015 simulation there were gained statistics of facilities load.

The most important handling facilities are cranes and transport vehicles (UNRA). Due to the model there were found out large disproportions between the crane load in working days and at the weekend. This is mainly about the dispatching cranes. It was performed the detail statistics for cranes at the new hall to gain a better view to activities of both cranes.

Mainly with the regard to the crane load and the vehicles cumulation there was mead a proposal to change a placement of parts of a new intended peeling line to the shape „U“. This implementation would change the crane work. The dispatching crane would fully devote to camion loading and the second crane which is operates the line would operate the input and also the output.

Results

On basis of this simulation experiment with the model of the presumed state in 2015 and the statistics which have been gained from this simulation there have been formulated few conslusions. We founded out that the crane capacity is satisfactory in the current operation of the annealing plant but the peeling capacities are not satisfactory, the load of the new peeling line are in critical values, the crane load will be higher, especially at dispatching cranes. The dispatching crane load at the new hall with the current logic of operators´ utilization reaches the critical level repeatedly.

Despite the layout of the dispatching warehouse along the processing line it will exists the crane blocation at the new hall and their effrot to help themselves will be problematic. There will be also queues of waiting vehicles for loading at the new hall (at the rush hour 6 camions).

For the planned state in 2015 there were proposed many recommendations, for example the creation of storage space in the current hall of annealing plant of stainless steel on the place of non-used facilities, the minimization of number of unloaded vehicles on weaned rails and in halls of annealing plant of stainless steel, the focus to size and quality structure at getting orders for peeling and think about the change layout of the new hall. The next thing that is recommend is to use the only one crane prefereably for the operation at the new peeling line and for material handling at input and the second crane use for the dispatching to avoid the mutual blocation.

These very loaded cranes at the new hall (especially the dispatching crane) caused the cumulation of waiting vehicles. On a working day there is 1 truck waiting for loading on average, at the rush hour up 6 trucks.