The optimization of the handling devices number: Hamé Inc.

The case study in pdf you can download here.

APPLICATION:

The optimization of handling technology

BRANCH:

Food industry

BENEFIT:

With the help of this project were the conclusions of the material flow analysis confirmed – the optimization of the number of handling technology. There was found the optimum variant according to the forklift and shift workload.

About the company

Hamé is the prime food industry company which is engaged in the production of lasting foodstuffs and cooled food. The tradition of the company began to twenties of the 20th century. HAMÉ Ltd. has in its portfolio these products: ketchupes, pâté, meat cans, vegetable products, fruit mixtures, jams, mayonnaise, tatar sauce, baggettes, sandwiches etc.

Project targets

The project target was the optimization of handling vehicles number in the Hamé company in Babice using the dynamic model in Witness 2003. This project continued the static analysis where the number of vehicles was determined on the basis of the current using of handling technology and which would fulfill all requirements implemented in Hamé Babice and at the same it would fulfill the criterium of the maximum using.

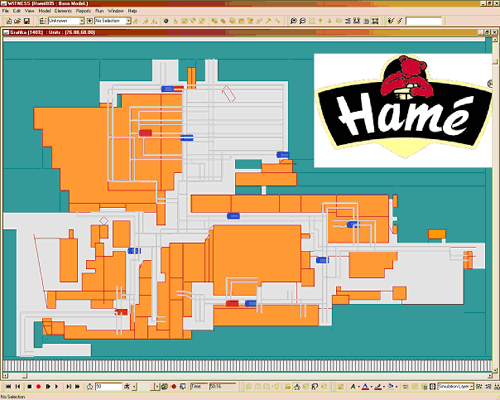

The simulation model demonstration

The simulated forklifts were dimensioned so that one forklift holds one full loaded pallet or two empty pallets. The set holds 5 MJ. During the simulation period (480 minutes = 1 shift) the ability of handling the needed material amount by given combination and number of handling devices was verified ath most critical period of the season in Hamé Inc.

The photo of handling device – the set type

Solution

During the project were confirmed the conslusions of the static analysis of the material flow – the optimization of handling vehicles number which have been implemented by the project preparation. There were proposed 21 forklifts (4 of them are used in satellite warehouses) to ensure the handling processes.

During the simulation of handling process with paletts in the production, warehouses and dispatching were supposed the maximum forklifts workload by data from the seasonal peak time where these requirements were equally decomposed during a shift.

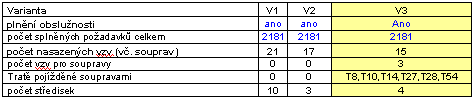

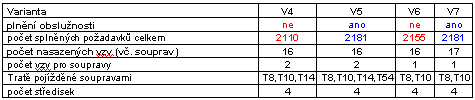

The variant no. 1 designed the current state in Hamé Babice and the others variants were different by numbers of handling devices, the structure of operated orders and using the sets.

The summary of simulated variants

From the 9 simulated variants was not appropriate the variant no. 4 and 6 because they are not able to ensure the fluency of product and dispatching processes. In the variants no. 3, 4, 5, 6, 7, 8, 9 were simulated different variants of using „sets“ from the viewpoint of their numbers and tracks on which them are used.

Results

The optimal variant is the no. 3 from the viewpoint of the handling devices number because there is possible to fulfill 2181 orders per a shift and use 15 forklifts in the Hamé area and another 4 forklifts in the satellite warehouses to ensure the opration at the Hamé company. There are included also the 3 sets of forklifts for the Babice company.

The simulated variants (except of no. 1) place increased demands for driving forklifts because their service is managed the individual requirements for handling, not forklift´ booking for the individual centers.